Suite 209

438 S. Emerson Ave

Greenwood, IN 46143 USA

+1-317-616-8183

info@medfab3d.com

Medical Providers Information Page

MedFab3D Introduction

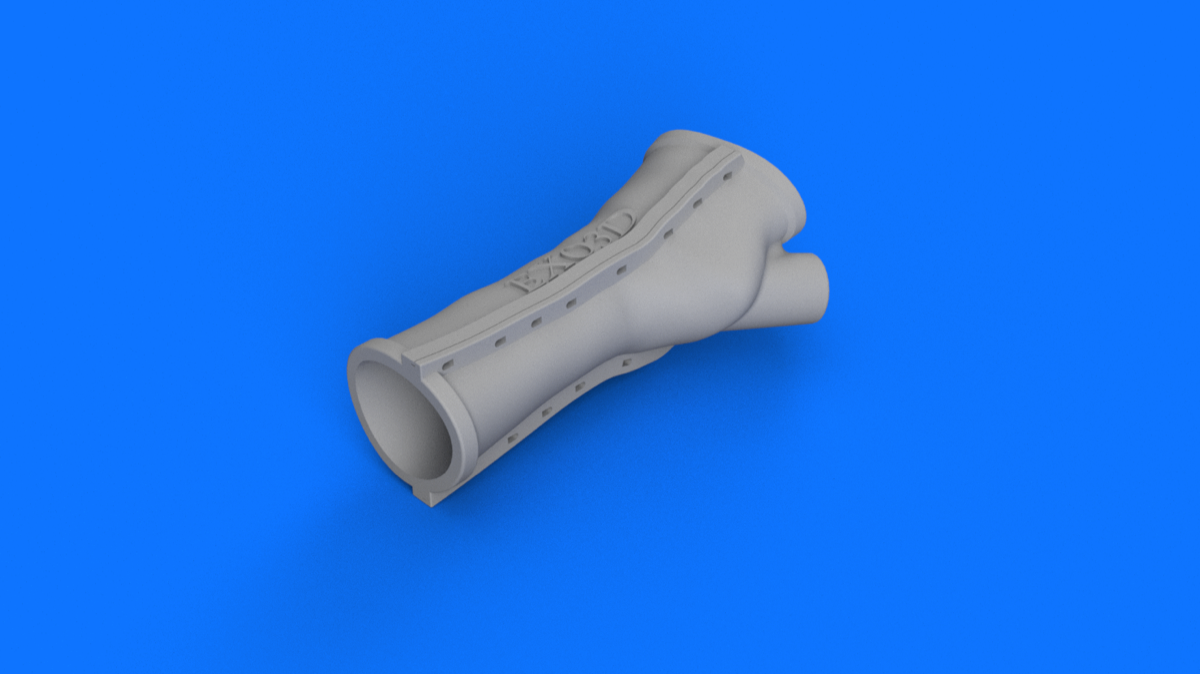

We would like to introduce our company MedFab3D. MedFab3D specializes in medical digital fabrication and design technologies. MedFab3D is local to the Indianapolis - Greenwood area. MedFab3D is FDA registered and fully insured to design and manufacture casts, braces and prosthetic components. The EXO3D casts are produced on MedFab3D's custom designed 3D printers and are made from a tough and durable FDA approved copolyester plastic. The EXO3D cast is delivered through the physician's office or clinic to the patient. Our delivery times for a cast, dependent on size, are typically 24 hours or less from the time of fit approval. MedFab3D provides complete support for measurement, application and removal of the cast during the training process and nothing is required to be purchased by your office to utilize this system. The EXO3D casts offer significant advantages to your patients for treatment. Our casts cost between $300 - $600 per cast dependent on size and type which is comparable to having a custom brace made. We provide an unconditional guarantee for our products and will be replace any cast or brace component that prematurely wears or becomes unusable at no charge. MedFab3D believes that this system represents the future for casting and brace technology and offers significant advantages to your practice over offices that utilize standard casting technology.

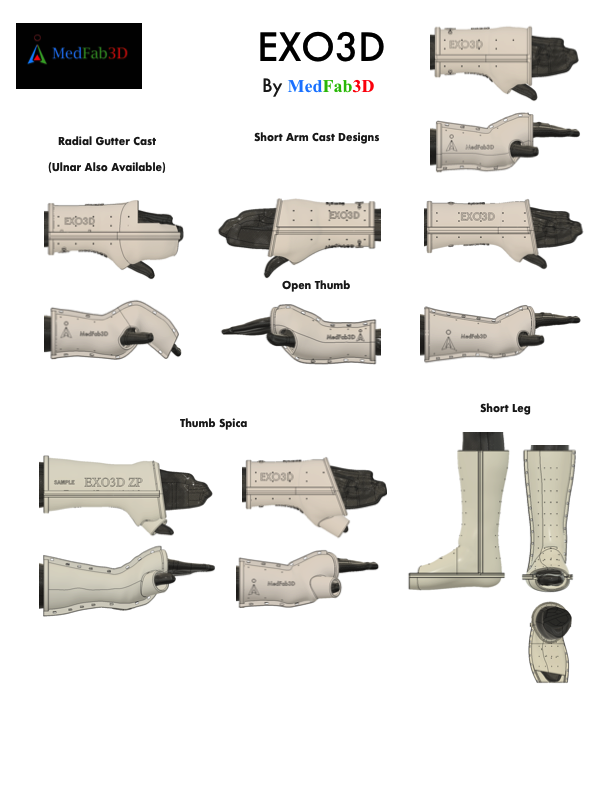

About the EXO3D Cast and Brace System

The EXO3D cast and brace system represents over 2 years of testing and development to commercialize digitally manufactured cast and brace technology and bring it to market. We realized during development of this system that the system needed to be easy to use. We provide all the services needed to utilize the EXO3D system as part of the cost of delivering the cast or brace including patient measurement for the cast at your office. The EXO3D cast is easy to apply and remove with application and removal typically taking minutes with our unique fastening system. The casts may be removed for examination, cleaning or imaging and may be reapplied with a new set of fasteners (provided free of charge). Before manufacturing the cast, we communicate the cast design and fit evaluation back with your office before producing the cast. The casts can have examination windows or ports added for bone growth stimulators as required for medical treatment. We stand behind our products and provide an absolute guarantee. We will replace any cast or brace that has become worn or unusable at no charge.

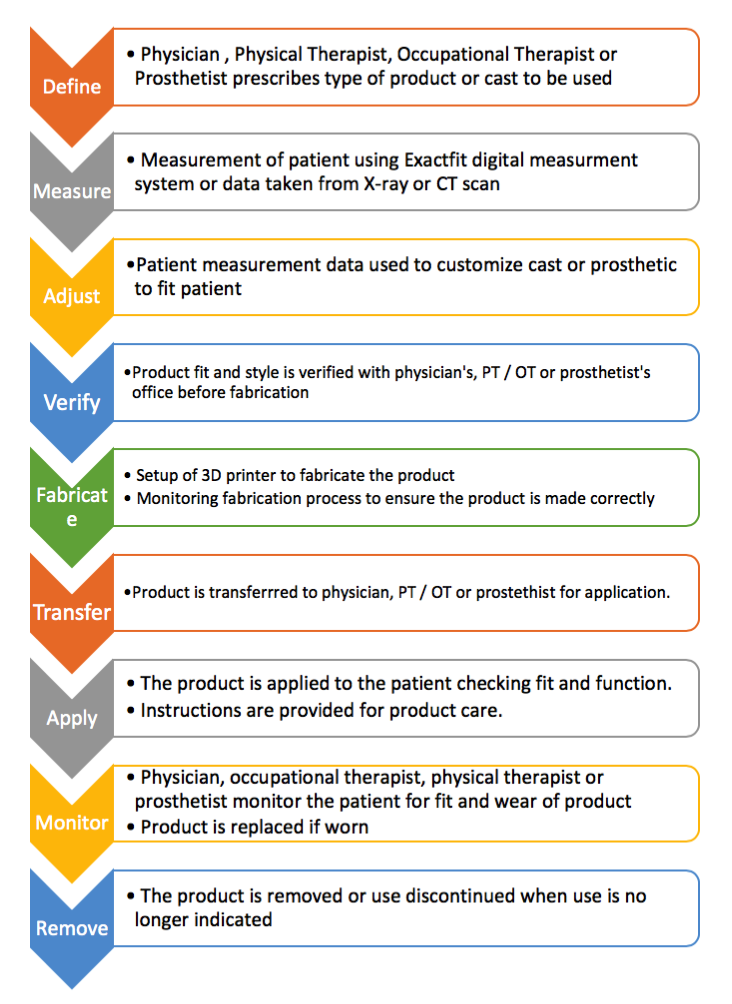

Product Delivery Workflow

Features

Custom Fit

Digitally Fabricated

(3D Printed)

Comfortable

Durable

Easy Removal

Patient is digitally scanned and measured for cast

Fit can be digitally evaluated before fabrication

Cast design can be reviewed by Physician or cast technician before fabrication.

Design can easily be modified if a fit issue is found during use

Cast is digitally fabricated after design at our local print lab

The cast can be reproduced exactly if damage occurs or the cast needs to be replaced.

Our equipment is specialized for manufacturing orthopedic casts with significantly lower operating costs than our competitors equipment.

Breathable

Lighter than a comparable fiberglass cast

Cooler when used with Delta-Dry padding compared to a fiberglass cast

Cast is smoother than fiberglass.

Can be worn in the shower.

Lower risk of skin breakdown due to improved hygienic nature of product

Waterproof when used with Delta-Dry padding

Stain Resistant

Strong and Tough

L-Pins of cast designed to absorb shock and can replaced if broken.

Cast is far less likely to replaced due to nature of design

Cast can be removed without a cast saw

Cast can be removed in minutes

Cast can be reapplied after removal with new L-Pins

Customizable for Medical Treatment

Clean

Innovative

Recyclable

Product Support

Surgical cast version can be sterilized

Easy removal for examination

Features can be added for bone stimulation or to facilitate pin removal

Padding can easily be changed when drainage is present from injury site

Cast material is easier to clean when compared to a fiberglass cast

Cast can be removed for cleaning and padding change

Cast can be cleaned with water while wearing

Improved Hygiene

Lower Risk of Odor

Dries Quickly

This is the future of orthopedic casting

Product is engineered for purpose

First digitally manufactured cast available in the US on a commercial basis.

Cast designs are parametric and cast design is generated from customized fit data take from a digitized scan of the patient

Fit of cast can be digitally verified before fabrication

Multiple designs for the end design can be evaluated to determine the best clinical approach when required

Cast can be removed and reapplied without loss of cast integrity

When our casts are no longer needed the cast can be recycled with other materials under the #1 Recycling Code

Free on-site training for medical staff to use the Exo3D cast system

On-site support to medical staff for cast delivery and removal

We unconditionally guarantee our product and will replace the cast at no cost if breakage occurs or a defect is found

Patient Benefits

Comfort

Stylish Design

Patient can continue active lifestyle as injury allows

Patient can shower and swim while wearing the cast

Cast can be cleaned to maintain hygiene

Padding of cast can easily be replaced if padding is worn or soiled

Less patient stress during removal

Reduced Odor

Provider Benefits

Higher Patient Satisfaction

Patient less likely to need to be recasted

Cast can be reapplied with new padding if a change is required

Technology will be a marketing benefit to attract patients to your organization or practice

The EXO3D cast system allows more options for patient treatment with customization potential

Technology is state of the art

Available Models

Short Arm

Thumb Spica

Ulnar Gutter

Radial Gutter

Short Leg